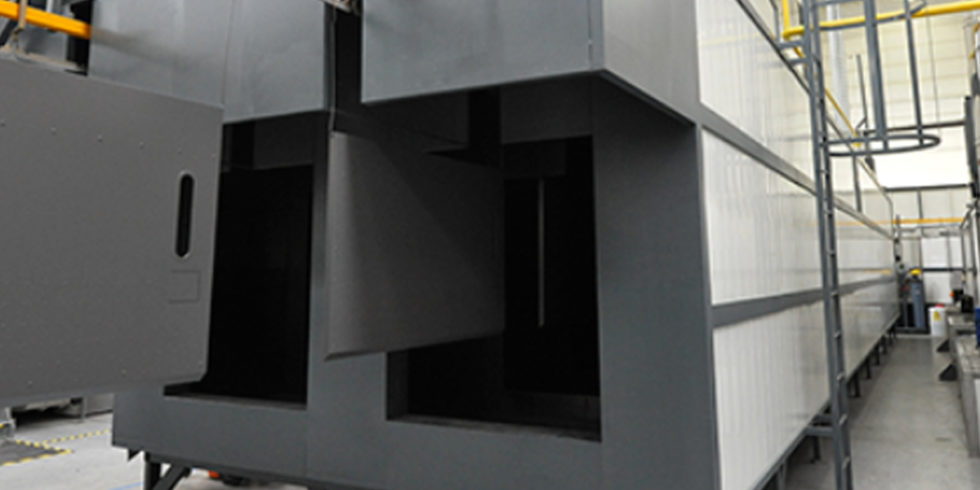

Two oven types:

- Low temperature ovens up to 250 ºC

- High temperature ovens up to 550 ºC

They are then divided into:

- Tunnel oven

- Box oven

3D designed channels for optimal heat distribution, which ensure our well-known even temperature distribution.

Special designed burner unit, either electrical or gas, with high class insulation and efficient ventilation units make sure that as much as possible of the airflow goes to ventilation.

The high quality construction of galvanized steel suits the oven temperature and purpose and improves the corrosion resistance.

The detachable steel cassettes on the outside of the oven make it easy to check and replace the insulation material. Service of the circulation and heating units is solely and unimpeded carried out from the outside of the oven.

The bearing capacity of the oven is not dependent on the insulation contrary to the construction of panel ovens.

Whether the drying/curing way, drying standard is right, or the design of equipment is rational, will affect its energy cost, coating film quality and coating cost directly.

Additional, energy saving and emission reduction is a strategic concept for developing economic. We can not ignore the energy cost of drying/curing device, environment pollution and some other question.

Heating energy used in drying tunnel can be steam, high temperature water, electricity, fuel gas, fuel oil, etc.