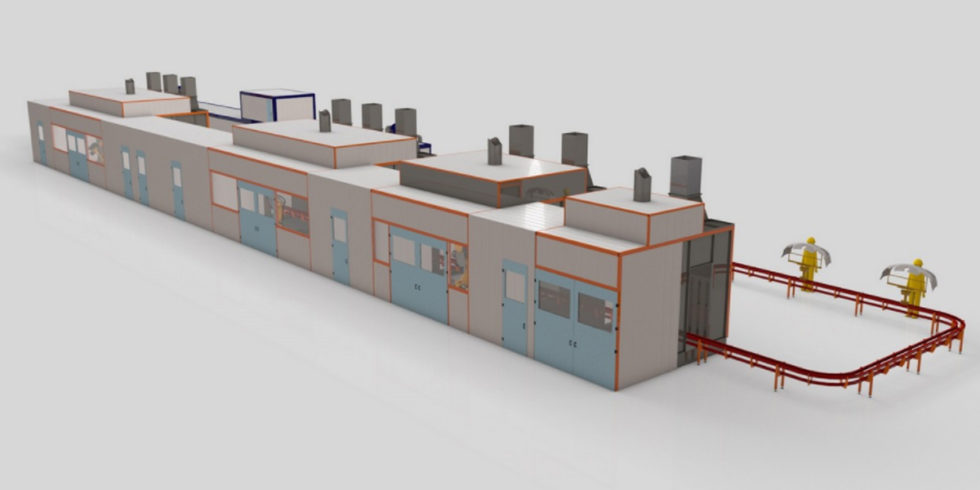

Charvies became the expert in designing and manufacturing liquid painting lines, including spray booths to fit system requirements. Our spray booths provide the ideal paint application conditions with balanced air flow to minimize overspray.

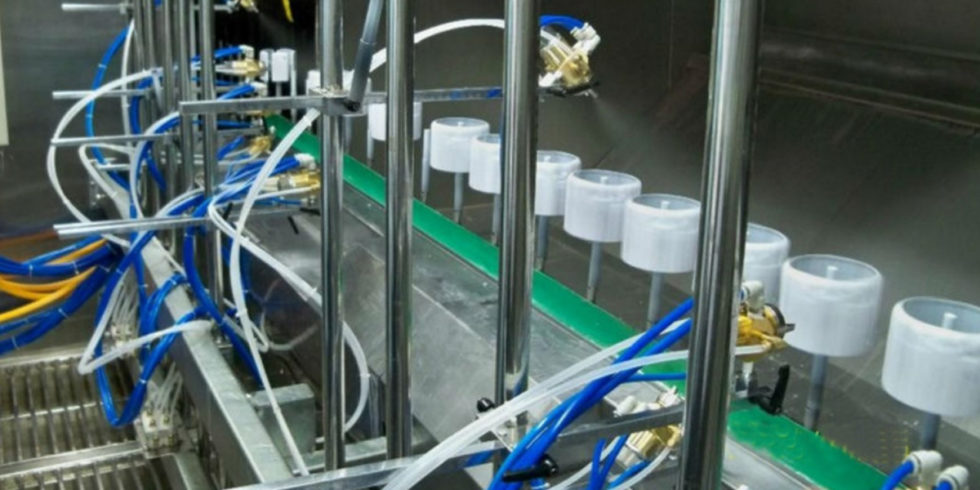

Charvies integrated recirculated air system, side –draft, cross-draft or down –draft air flow, multi-level filtration, powered man-lifts, conservative air flow, high efficiency dry filter or water wash filtration , high intensity lighting, paint sludge separation and other innovation to make the customers easy to operate and save resources and cost.

Available facilities:

- Recirculated air systems

- Side-draft, cross-draft, down-draft or multi-level air flow

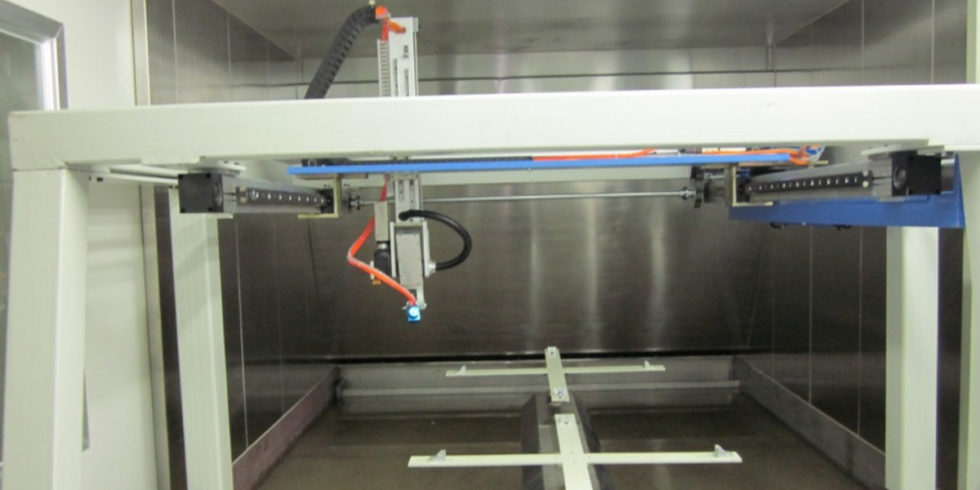

- 3-axis air-powdered man-lifts

- Conservative air flow

- High efficiency water –wash

- Dry filter

- High density lighting

- Designed for robotic use

- Combination spray and cure

- VFD controled fan and air flow control

Practical applications:

Whether the customer needs a booth designed for complete automation or manual application, Charvies spray booths offer the highest quality features. Our engineers evaluate the specifications and design equipment that best suits the production rate, space, airflow requirements and material handling needs. Charvies liquid spray booths are open-faces enclosed, multilevel, large equipment or small part sized; custom designed per the spercifications.

Cost effectiveness

High efficiency water-wash booths capture the paint particles with more than 99% effectiveness. Recirculating air systems, automatic VFD’s, and LEL(LOWER EXPLOSIVE LIMIT) monitoring dramatically reduce cost by minimizing capital and operating expenses.

The experts at Charvies company try their best to design the most cost effective, energy efficient and environmentally friendly booth.